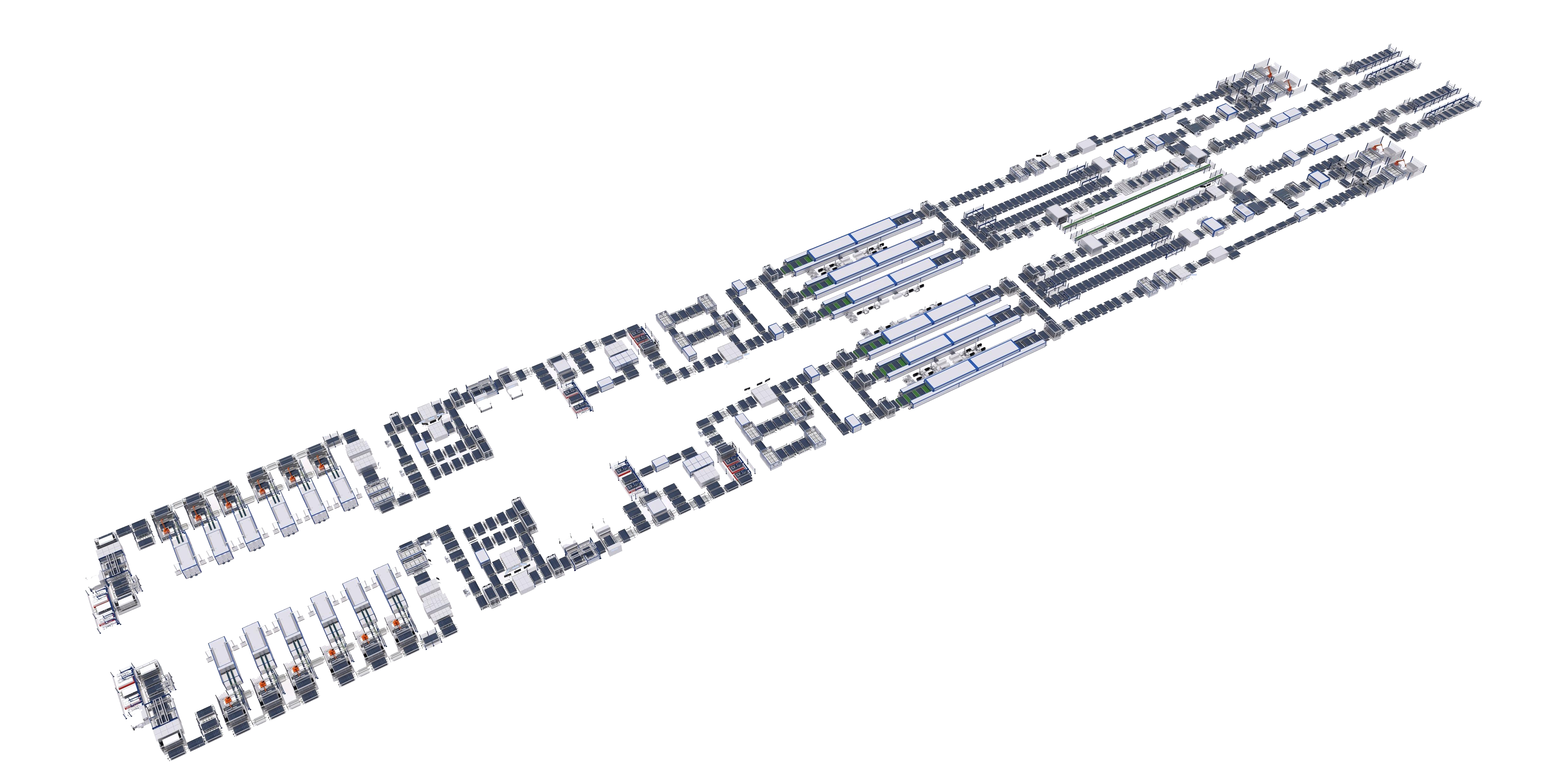

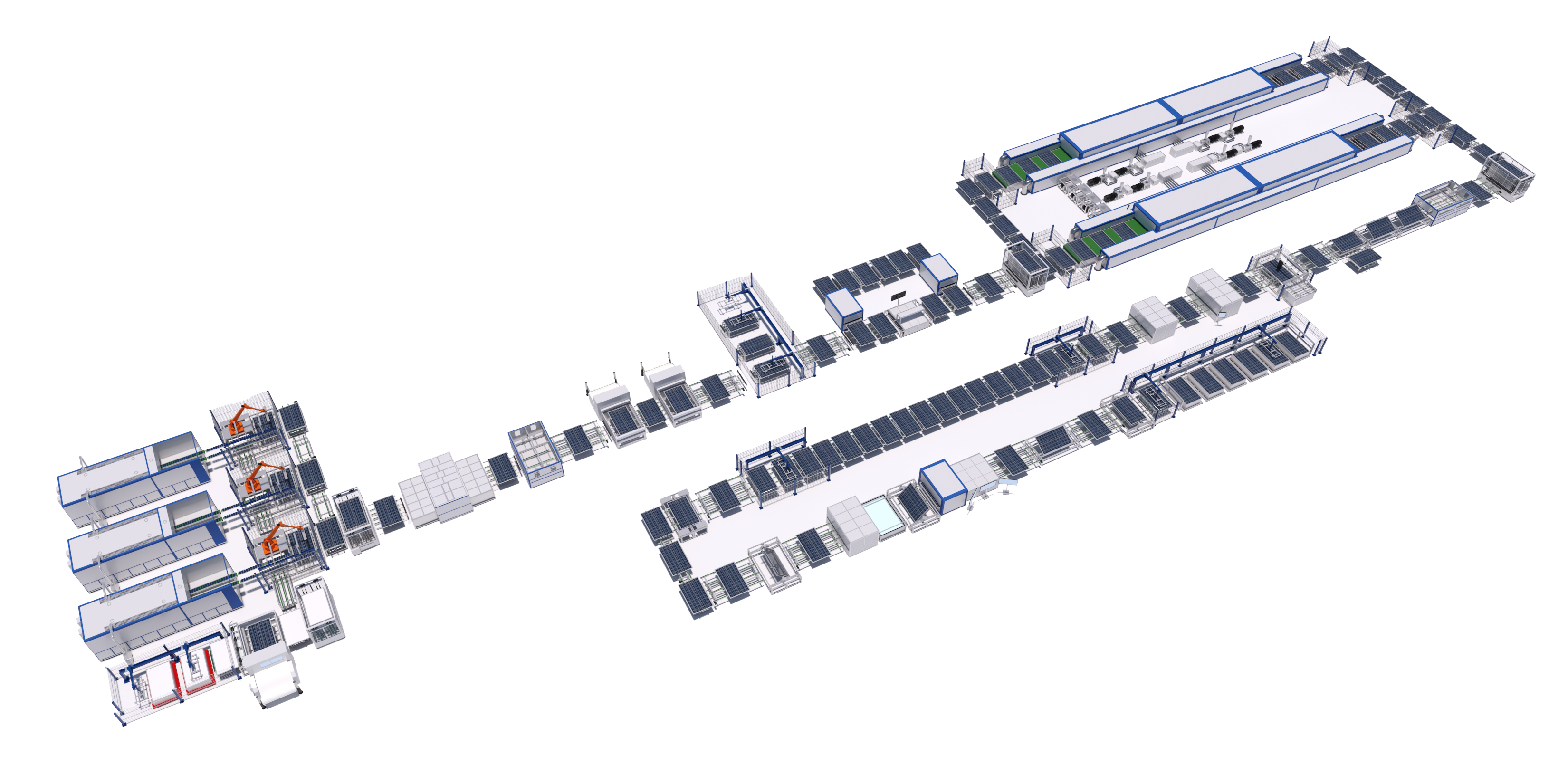

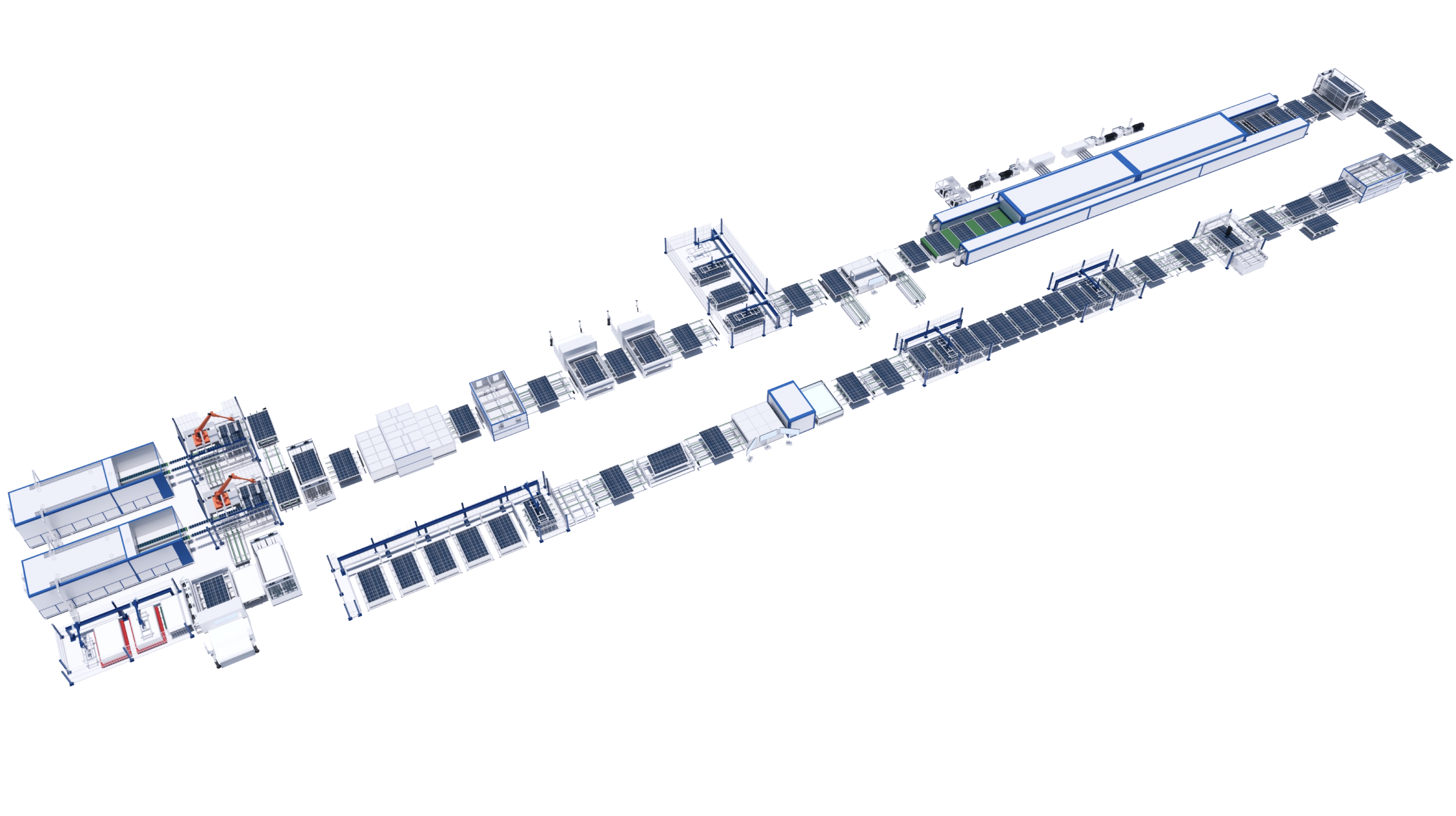

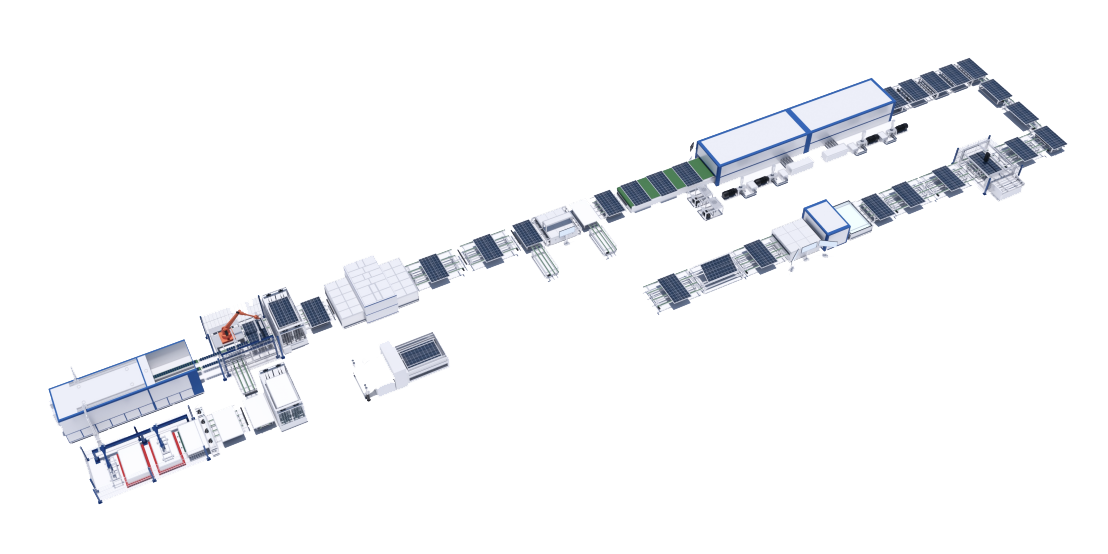

150MW

1000m²

Production area

150MW/Year

Production Capacity

5/per shift

Operator

1128PCS/ day

Qty of Solar module

1

STRING WELDING MACHINE

2

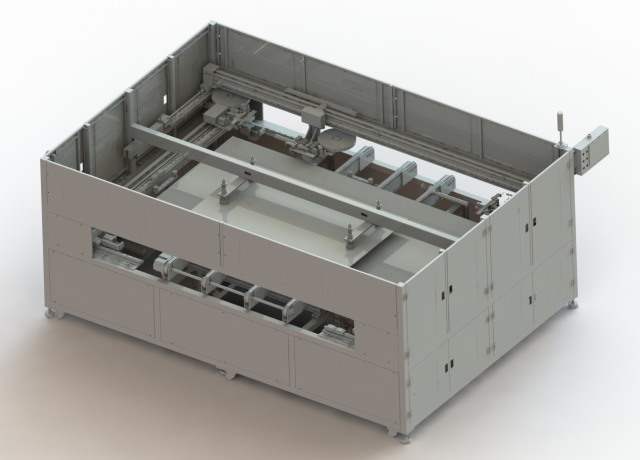

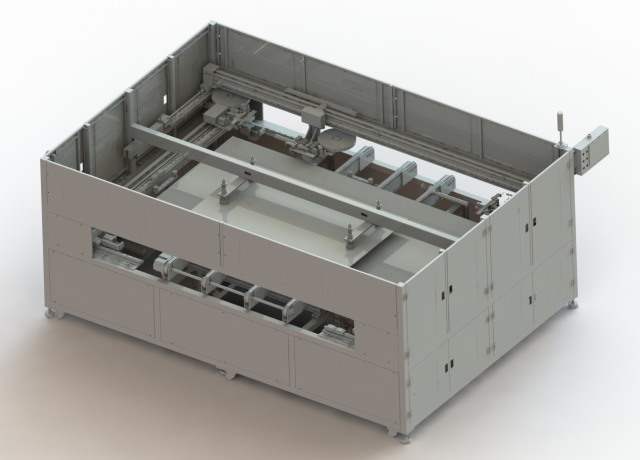

AUTOMATIC ROBOT TYPESETTING MACHINE

From the first device to grab the battery string, judge for themselves whether to turning,after rotation is completed in a safe location, by the laser correlation photoelectric get batterystring space coordinates, and then through the manipulator angle correction, complete layoutof battery string.

Detail

3

GLASS FEEDING MACHINE

4

AUTOMATIC EVA CUTTING AND LAYING MACHINE

5

FULLY AUTOMATIC BUSBAR WELDING MACHINE

Automatically complete the interconnection soldering process of the PV module bus bar including thearrangement of the junction box end and the non-junction box end, the cutting & bending of busbarand the soldering of ribbon and busbar.

Detail

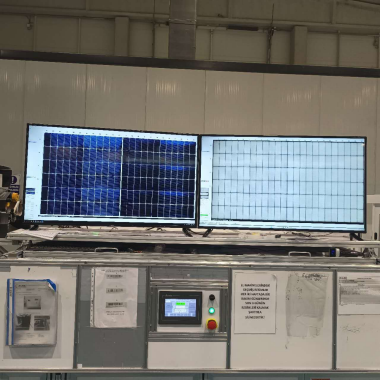

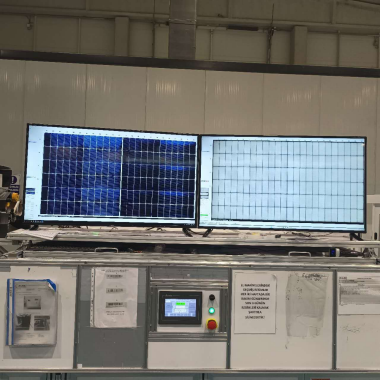

6

ONLINE EL/BVI SCANNER

7

DOUBLE-GLASS AUTOMATIC EDGE SEALING MACHINE

The four sides of the double glass adopt a belt servo drive mechanism. After the doubleglass enters, it returns to the right, the lower suction cup mechanism is lifted, and thesuction cup is vacuumed when it is in place. The four sides of the tape drive the fixtureto stick the tape.

Detail

8

DOUBLE-LAYER LAMINATOR

9

FULLY AUTOMATIC GLUING AND FRAMING MACHINE

A fully automatic framing machine, integrating the functions of frame loadinggluing, frame catching, framing and conveying; it greatly improves the production efficiency byaccomplishing the technological process of module's gluing and framing.

Detail

10

ONLINE EL/BVI SCANNER

11