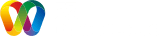

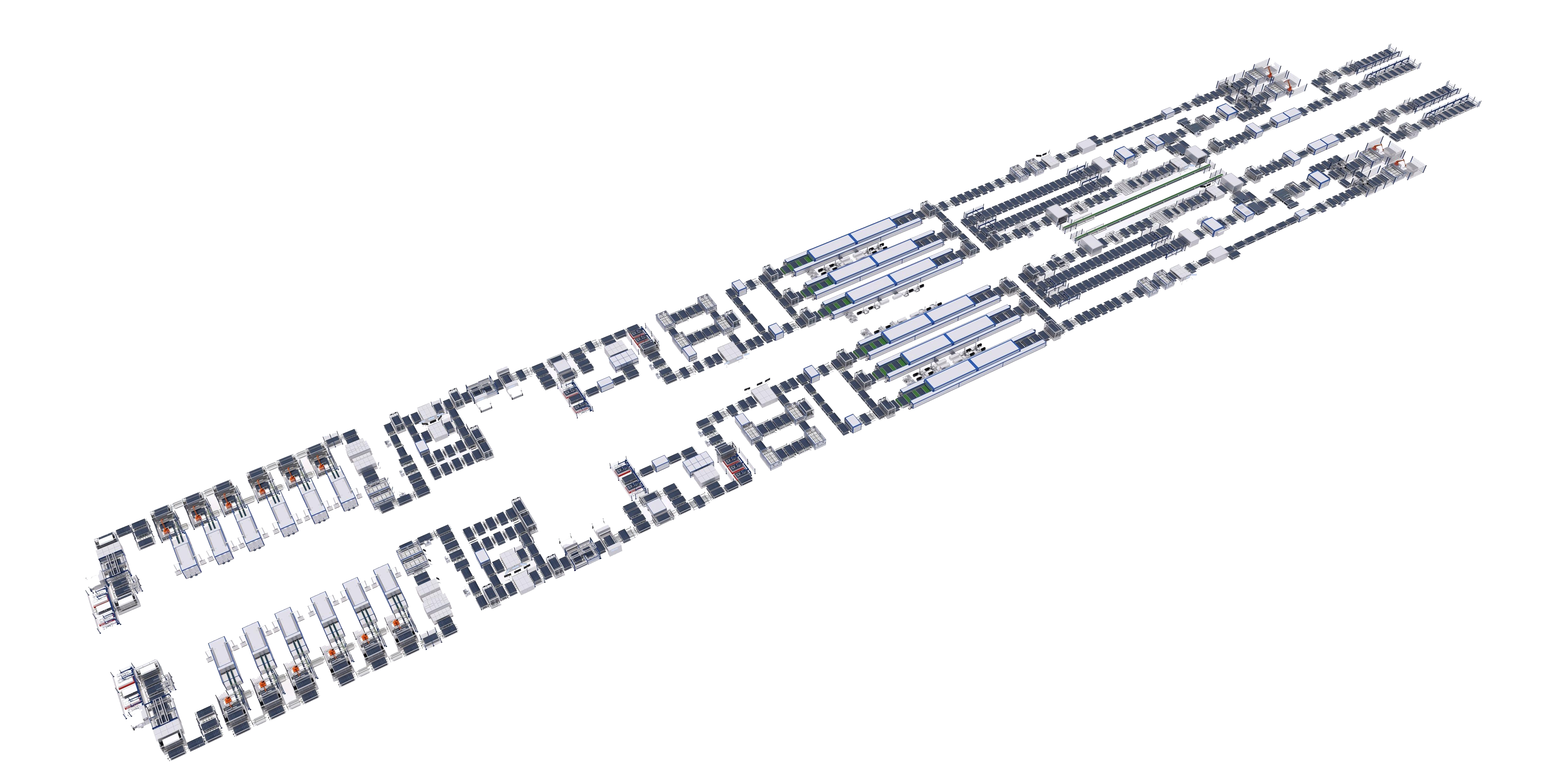

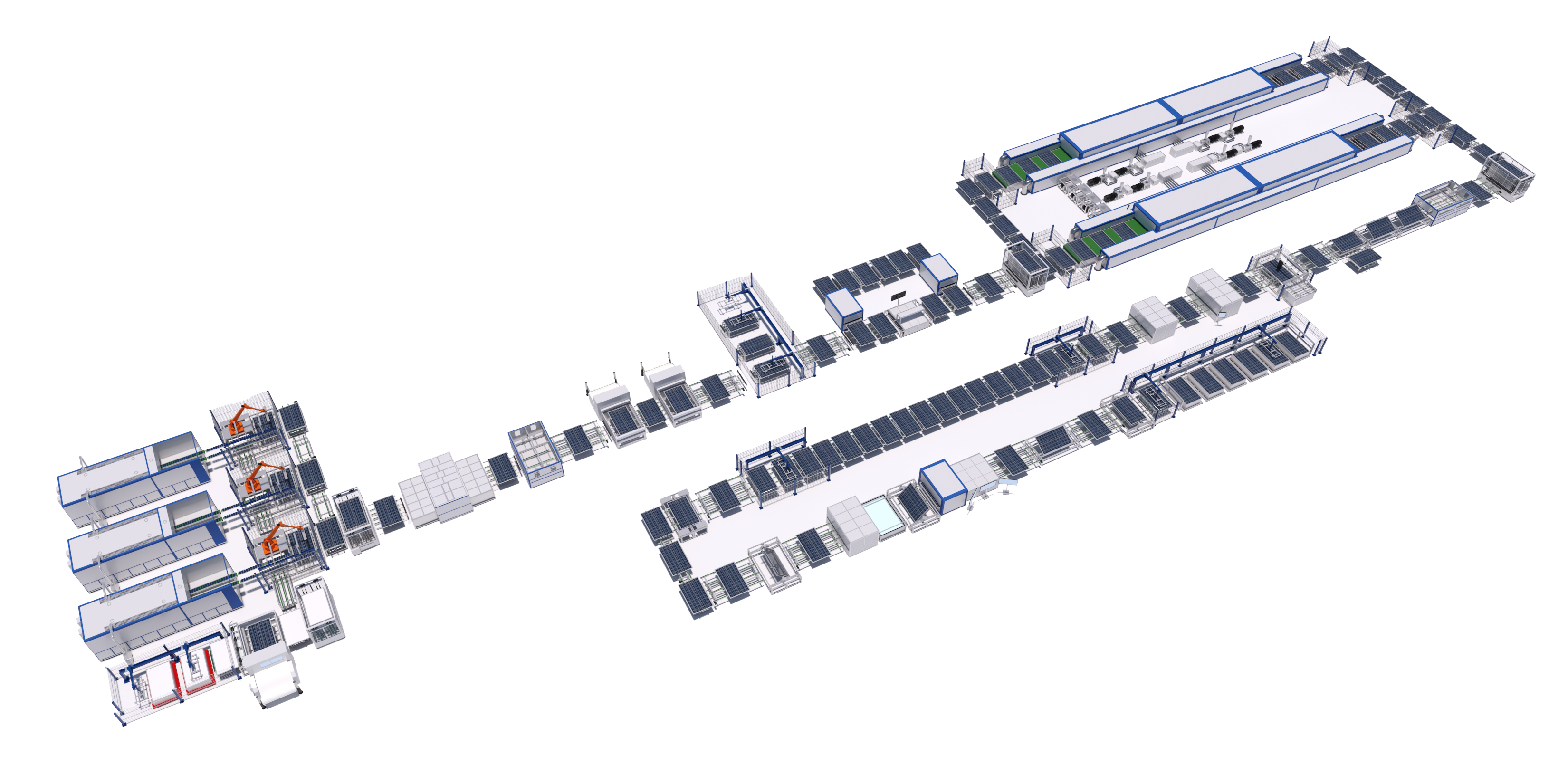

600MW

3500m²

Production area

600MW/Year

Production Capacity

11/per shift

Operator

3384PCS/ day

Qty of Solar module

1

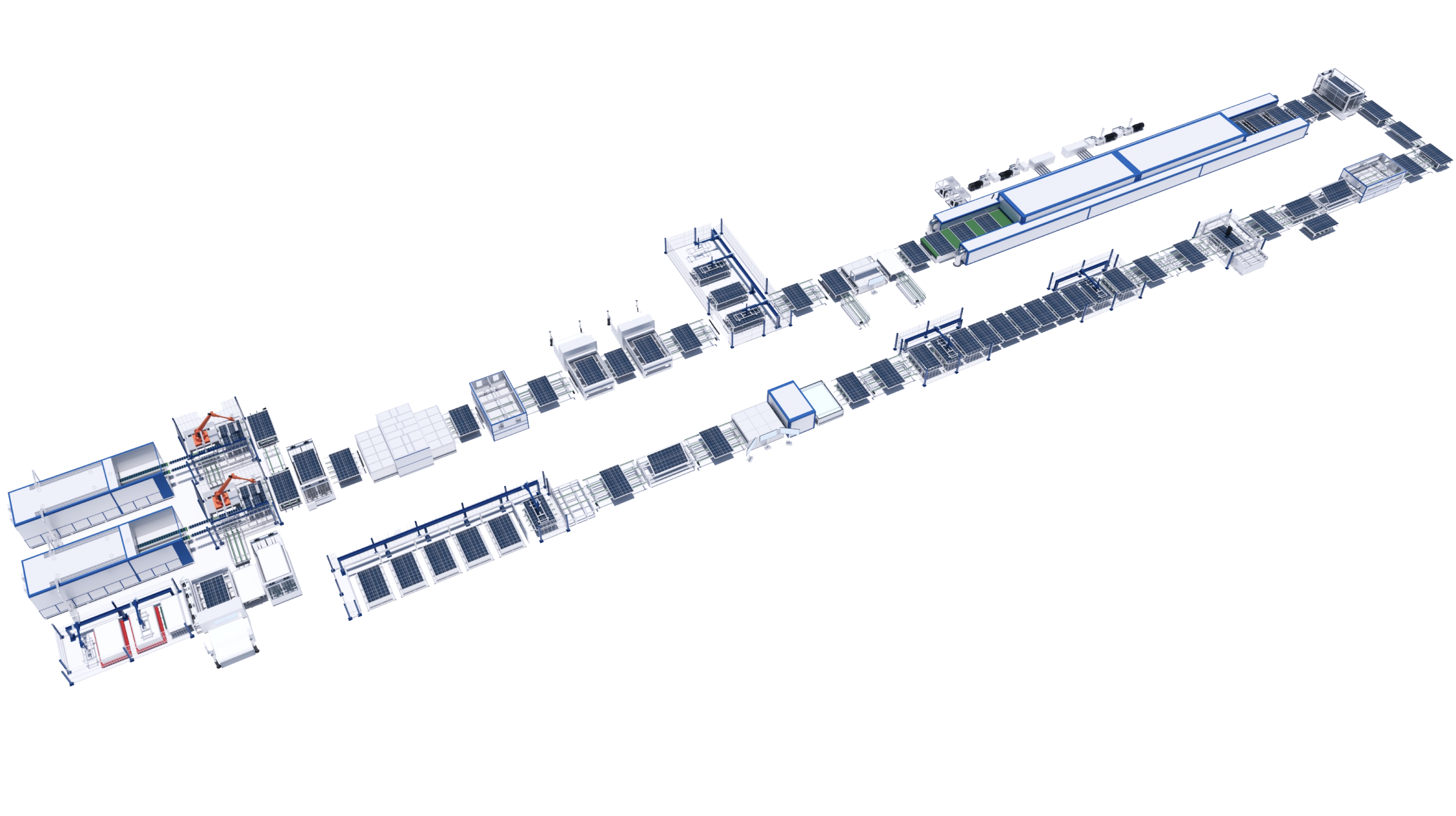

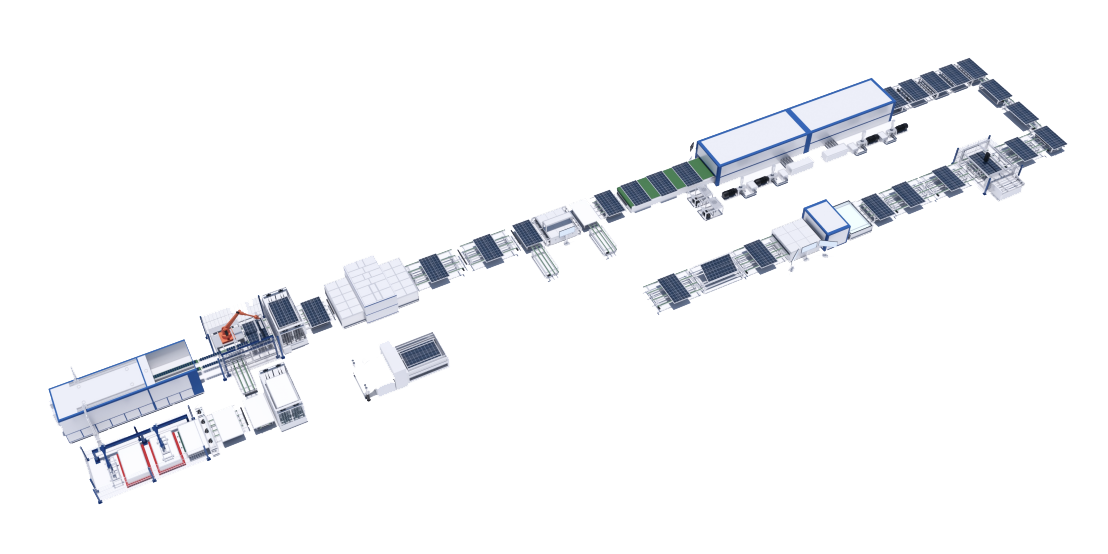

String Welding Machine

2

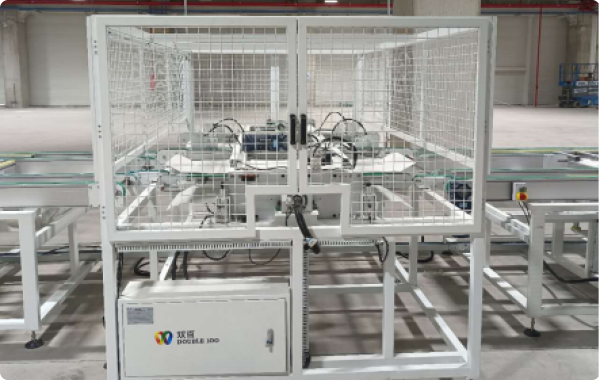

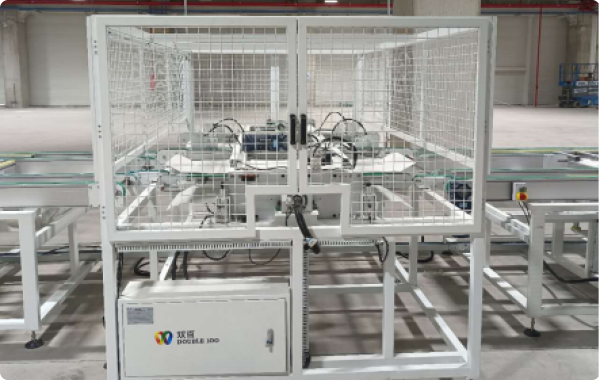

Robot Typesetting Machine

From the first device to grab the battery string, judge for themselves whether to turning,after rotation is completed in a safe location, by the laser correlation photoelectric get batterystring space coordinates, and then through the manipulator angle correction, complete layoutof battery string.

Detail

3

4

Automatic EVA Cutting and Laminating Machine

Equipment Function: Used for cutting, punching and notching of EVA, TPT etc.

Detail

5

Fully Automatic Busbar Welding Machine

Automatically complete the interconnection soldering process of the PV module bus bar including thearrangement of the junction box end and the non-junction box end, the cutting & bending of busbarand the soldering of ribbon and busbar.

Detail

6

Automatic Tape Machine

The automatic adhesive tape between the battery strings is realized. When the number of adhesive tapesis pasted, the speed fast, replacing the manual labor greatly and improves the working efficiency, and theadhesive position is accurately, without causing secondary damage to the battery.

Detail

7

Automatic EVA Cutting and Laminating Machine

Equipment Function: Used for cutting, punching and notching of EVA, TPT etc.

Detail

8

Double Glass Laminating Machine

Combine the second piece of glass with the first piece of glass.

Detail

9

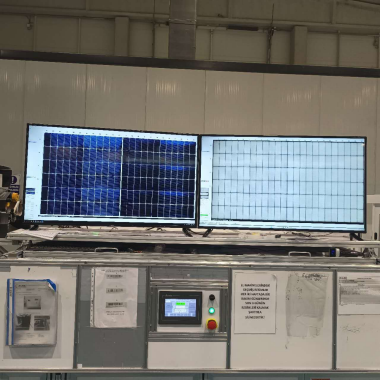

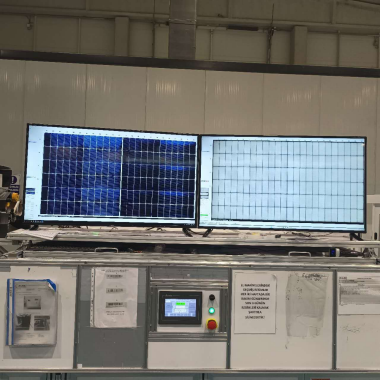

Online EL/BVI Scanner

10

Double Glass Repair Robot Arm

The equipment includes a vacuum suction mechanism, a transmission mechanism, and a safety limit mechanism.

Detail

11

Lifting Machine

Rise/descend control, achieving smooth upward and downward movement of the equipment, supporting multiple height adjustments.

Detail

12

Double-layer Laminator

13

Automatic Edge Cutting Machine

This unit is mainly applied to remove and clean the remains of excessive glueof the modules after laminated; it works self-acting cutting through program setting whichcan smoothly remove module's redundant remains.

Detail

14

90° Flip Inspection

Conveying method: synchronous belt conveyor assembly with positioning function.

Detail

15

Fully Automatic Gluing and Framing Machine

A fully automatic framing machine, integrating the functions of frame loadinggluing, frame catching, framing and conveying; it greatly improves the production efficiency byaccomplishing the technological process of module's gluing and framing.

Detail

16

Junction Box Laser Welding Machine

The J-box soldering machine is an automatic soldering equipment for solar moduleThe soldering method :laser soldering

Detail

17

Junction Box Glue Filling Machine

18

Curing Line Loading Robot

Stack the modules on the curing line after positioning and aligning.Placethe modules onto the production line automatically after curing.

Detail

19

Curing Line

The equipment uses a steel structure welded frame, which has high strength and ensures the entire machine is firm and reliable during transmission.

Detail

20

Curing Line Unloading Robot

Stack the modules on the curing line after positioning and aligning.Placethe modules onto the production line automatically after curing.

Detail

21

Automatic Corner Grinding Machine

The fully automatic chamfering machine is mainly used for deburring the four corners of the rear frame after the photovoltaic module framing.

Detail

22

Junction Box Lid Sealing Machine

Realize automatic installation of solar module junction box cover, improve installation efficiency and quality.

Detail

23

Insulation Resistance Tester

24

Solar Cell Module Tester

25

Online EL/BVI Scanner

26

Final Appearance Inspection

27

Automatic Sorting Machine

Automatically identify power levels and the level number able to be automatically adjusted as per production requirement.

Detail